- The Indian Ocean region is biodiverse, and its unique oceanic characteristics pose a significant challenge of biofouling for vessels.

- Baseline studies are required for a holistic understanding of biofouling species, and appropriate antifouling measures should be adopted.

- Antifouling coatings are the conventional techniques but may cause potential environmental degradation. Ultrasonic antifouling systems are on the rise.

- The oceanic conditions significantly affect the efficient operations of acoustic sensors and require modifications to the vessel’s systems.

- UDA must be understood to develop systems catering to the regional conditions.

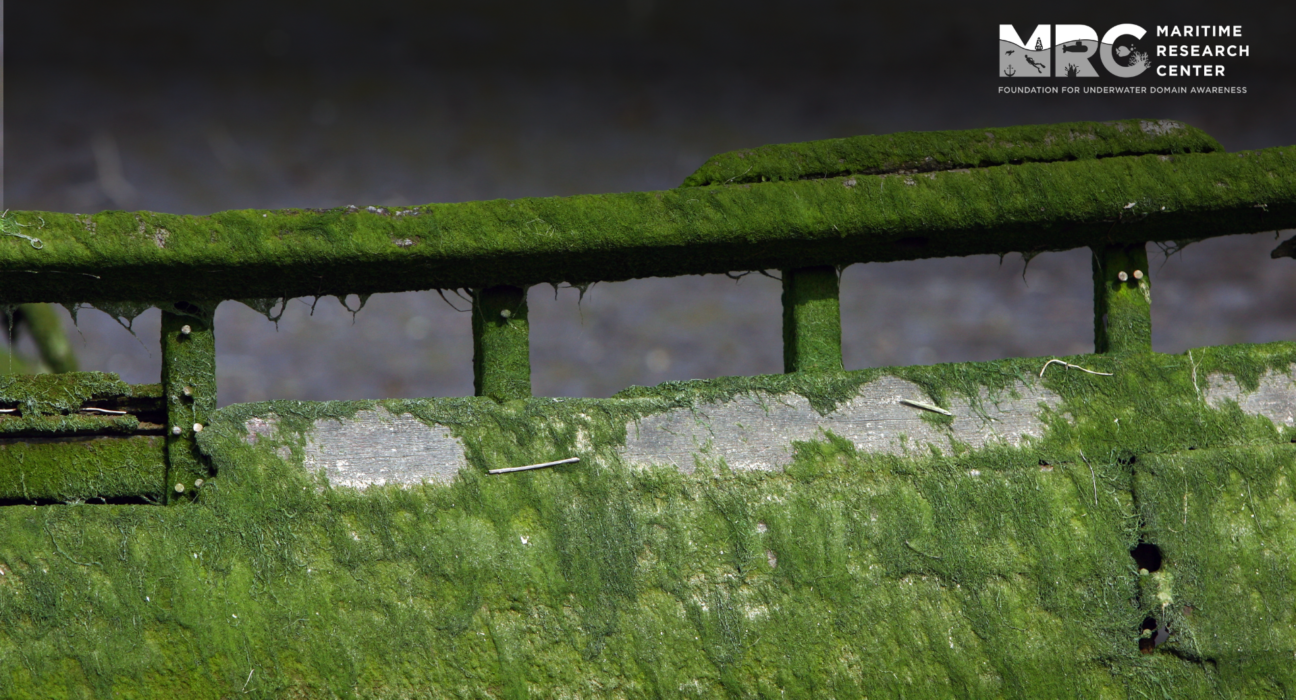

Ocean shipping constitutes approximately 90% of global trade, with the Indian Ocean Region (IOR) serving as a vital maritime trade hub for centuries. It is the busiest trade corridor, facilitating around four-fifths of the world’s oil and gas shipments and one-third of bulk cargoes, ensuring global access to essential resources such as food, precious metals, and energy. The IOR holds strategic significance, drawing attention from major global powers. Sustaining many cargo ships becomes imperative due to the challenging climatic, biological, and chemical conditions at sea. In tropical environments, biofouling poses a significant challenge for commercial ships, boats, and recreational yachts. Naval vessels, including destroyers, aircraft carriers, and frigates, are particularly susceptible to biofouling due to their unique characteristics—they operate at high speeds but spend a substantial amount of time at anchor. Biofouling is defined as the undesirable biological growth on the exposed underwater surfaces of these vessels. The elevated temperatures and abundant nutrients in tropical waters foster the development of marine organisms. The maritime community and shipbuilders have been addressing the adverse impacts of biofouling on ships for centuries. Initially, there were two primary concerns, with the first, now uncommon in commercial shipping, involving the rapid deterioration of wooden hulls below the waterline due to wood rotting fungi. The second challenge, still prevalent in contemporary commercial shipping, pertains to the impact of biofouling on a vessel’s speed and manoeuvrability. Additionally, there are repercussions related to corrosion, blockage of seawater systems, and effects on fuel and cargo. While issues such as the dead weight of biofouling organisms and the obscuring biofilm on the hull are not as pronounced on ships as on offshore platforms, biofouling’s economic and operational costs remain significant in the shipping industry. This translates into increased power requirements, leading to higher fuel consumption or reduced speed for the same power. In both scenarios, financial expenditures rise, contributing to heightened environmental damage.

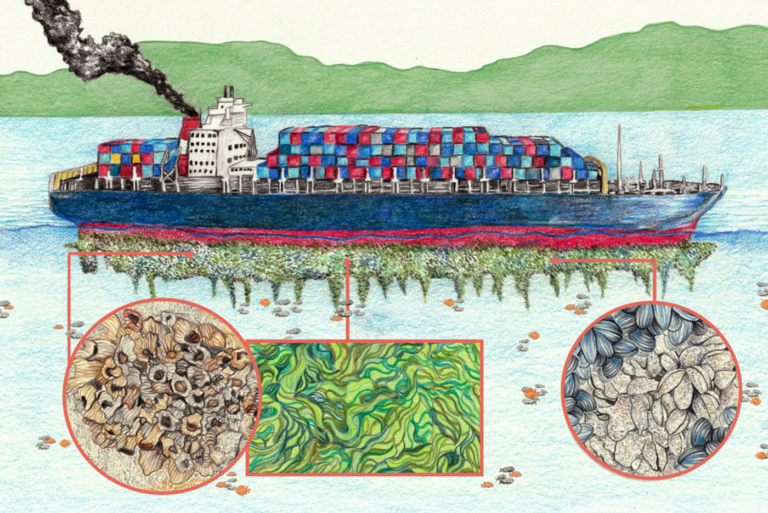

Conducting baseline studies is essential to comprehend biofouling’s causative factors on hulls and develop effective antifouling technologies. Biofouling can be broadly categorised into macrofouling, involving the colonisation of multicellular macro-organisms like macroalgae, barnacles, and tubeworms, and microfouling, which encompasses the colonisation of microscopic organisms such as bacteria, Cyanobacteria, and the polymeric slimy substances they generate. These substances facilitate the adhesion and growth of these organisms on surfaces. The measurement, monitoring, and regulation of physicochemical parameters in the environment are pivotal in mitigating biofouling. Factors such as the availability of larvae in the local ecosystem, the presence of necessary nutrients, and variations in sunlight penetration at different depths, among others, act as limiting factors for the recruitment of various biofouling organisms. Environmental variables like pH, salinity, flow rates, and temperature influence and modulate fouling.

The utilisation of anti-fouling coatings represents one of the earliest antifouling methods, with practical commercial applications dating back to around 1860. Antifoulants are commonly incorporated as additives in the topcoat paint of marine protective coating systems. These chemicals are gradually released into the saltwater, impeding the attachment of barnacles and other marine organisms to the ship. The effectiveness of certain biocides varies against different forms of fouling, and copper, for instance, demonstrates high efficacy against a broad spectrum of fouling organisms, particularly immobile invertebrates such as barnacles and tubeworms. These paints are extensively applied to vessel hulls and typically require reapplication every 1–3 years.

Despite their effectiveness, research indicates that the residual presence of these substances in the water can lead to the mortality of marine organisms, causing damage to ecosystems and infiltrating the food web. Tributyltin (TBT), an organotin chemical identified in the 1960s, is a highly efficient biocide employed in anti-fouling paints. However, the accumulation of TBT in the environment risks marine ecosystems, given its persistence and bio-accumulative properties, resulting in long-term consequences. Extensive research has been conducted on natural product biocides over the years, and while some exhibit notable antifouling properties, further investigation is required to assess their environmental impact.

In 1989, the International Maritime Organization (IMO) acknowledged the adverse environmental effects of organotin compounds. In 1990, the IMO’s Marine Environment Protection Committee (MEPC) recommended that governments take measures to eliminate anti-fouling paints containing TBT on non-aluminium-hulled ships. Subsequently, in November 1999, the IMO adopted an Assembly resolution instructing the MEPC to develop a globally binding instrument to address the harmful effects of anti-fouling systems on ships. The resolution called for a worldwide ban on the application of organotin compounds in anti-fouling systems by January 1, 2003, and a complete prohibition by January 1, 2008. Antifouling companies have since engaged in significant research and development to create marine coatings that offer economic benefits without associated environmental drawbacks.

With technological advancements, electrolytic systems became one of the most commonly used systems to fight biofouling on ships. The electrolytic system has pairs of anodes, mainly copper and aluminium. An electric direct current is conducted through the copper anodes, generating ions that are transported with saltwater throughout the whole pipe network. The presence of copper ions in saltwater inhibits the attachment and proliferation of marine organisms on the surface of the pipes. The purpose of the second anode is to inhibit the corrosion of the metal surface. The iron anodes inhibit the degradation of metal oxide coatings by corrosive substances present in saltwater. A control panel gauges and oversees the production of each of the anodes.

Acoustic systems are widely acknowledged as highly effective in preventing biofouling, claiming to reduce it by up to 80%. The use of acoustic techniques for biofouling management emerged in the 1980s, employing a signal generator, power amplifier, and piezoelectric transducers (projectors). These ultrasonic anti-fouling systems emit high-frequency sound waves (>20 kHz) into the water, creating an unfavourable environment for marine organisms to attach and thrive. The sound waves lead to the formation of tiny bubbles, causing intense shock waves that disrupt the adherence process of marine creatures. Additionally, the sound waves create a thin protective gas layer, acting as a barrier to prevent fouling. A notable advantage of this system is its non-invasive nature, as no components directly contact the seawater.

Studies indicate that ultrasonics exert two discernible effects on anti-fouling. Firstly, high-frequency vibrations create an inhospitable environment, unsettling organisms. Secondly, a mechanical intervention occurs, impeding the attachment of organisms and targeting those already affixed. This intervention prevents solidification and addresses organisms that have already adhered. Additionally, the characteristics of the ocean impact signal features, with tropical conditions posing specific vulnerabilities to ultrasonic systems. These systems, predominantly manufactured by Scandinavian and American companies, are tailored to the conditions prevalent in these regions.

Variances in salinity levels necessitate the calibration of acoustic systems. Changes in water depth and density can lead to differential refraction or reflection of sound waves, affecting the coverage and efficacy of acoustic antifouling systems, especially in regions with diverse seabed topography. The tropical waters of the Indian Ocean, known for their high biodiversity, result in differential absorption of sound frequencies, where some frequencies are absorbed more readily than others. Lower-frequency sound waves, less absorbed, are more suitable for long-range communication. Using acoustic antifouling systems may impact these organisms, potentially causing unintended consequences in the ecosystem.

The baseline studies would enable us to understand the desired characteristics and antifouling measures. The next step would include the procurement of hardware. The presence of supplementary hardware components for scalability is crucial in such instances. It is necessary to ensure the quality, feasibility, and serviceability. The presence of hardware might influence the schedule of system installation and upkeep. Hardware procurement delays may result in prolonged inactivity, which can incur significant expenses for the defence forces. When acquiring hardware, it is crucial to consider the accessibility of warranties and support services.

Understanding the vessel systems is another challenge. Various categories of vessels may possess distinct specifications for antifouling systems. To ensure the safety of ships, it is crucial to have a comprehensive understanding of the existing systems and rules about ship alterations. Integrating the selected system with the ship’s communication, control, and monitoring systems is essential. Modifications to the ship’s hull may be required to permit the installation of ultrasonic transducers, depending on its present design. It is necessary to verify the compatibility of all hardware components and the antifouling system. Incompatibilities may result in system breakdowns and incur extra expenses for replacement or modification. Compliance with regulatory norms or certifications may be required for the hardware used in ultrasonic antifouling systems. Ensuring that the hardware fulfils these standards is crucial to prevent legal and compliance complications.

Upon successful installation, it is imperative to establish a monitoring system to track the operation of the antifouling system, providing real-time data on fouling conditions and the effectiveness of ultrasonic treatment. This data can be analysed to identify fouling trends and improve the performance of the ultrasonic antifouling system over time.

The user-industry-academia partnership is vital for leveraging the demographic dividend and ensuring the region’s secure, prosperous, and sustainable socio-economic development. Marine Spatial Planning and Biotechnology will contribute to recognising the full potential of antifouling systems, benefiting stakeholders ranging from small fishing boats to commercial operators and naval forces. Sustained efforts will safeguard our neighbourhood, progressing towards a secure, prosperous, and sustainable socio-economic development.

Romit Rajendra Kaware

About Author

Romit Rajendra Kaware is a recent graduate from the Indian Institute of Technology Delhi, holding a Bachelor’s degree in Civil Engineering. Currently, he is serving as a Research Fellow at MRC. His primary focus is on scientific research in structures and materials, as it enhances his comprehension of the methodologies employed in constructing resilient infrastructure. Romit is deeply enthusiastic about applying his expertise in civil engineering to the maritime sector to foster sustainable development for our ecological resources.